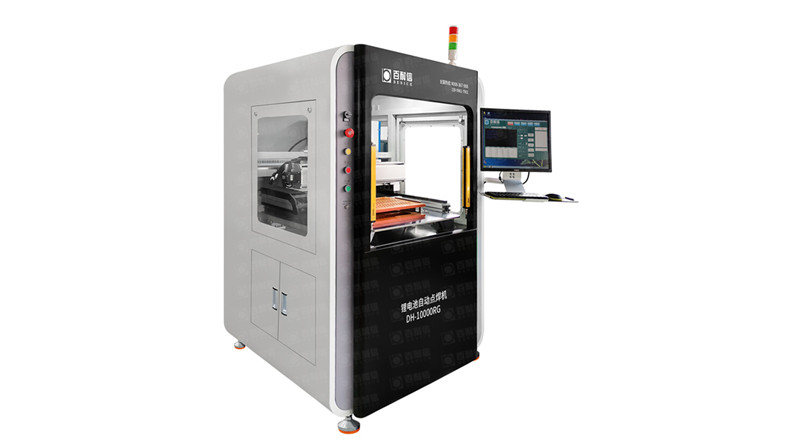

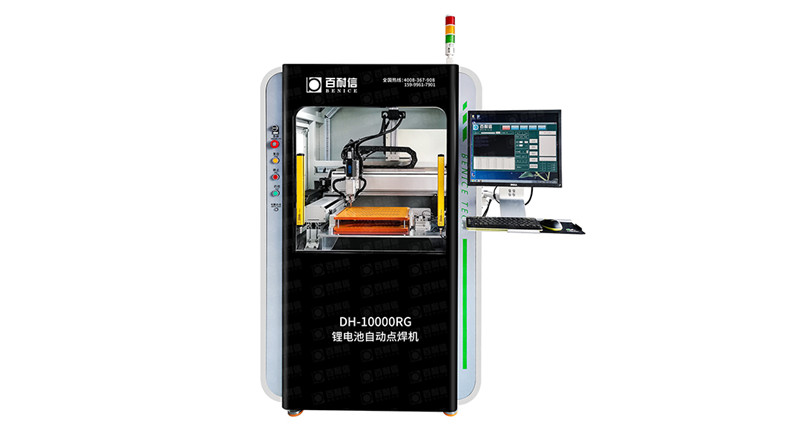

Lithium battery welder 10000RG

Product Features

It is essential to prepare the lithium battery spot welder for cleaning before welding. Foreign matters, such as oil stains, often appear at the upper and lower electrodes, which requires us to clean regularly.It may be a trivial matter in life, but it may be because it causes us to fail when using the spot welder safely. It is easy to clean up, but we must do it often.

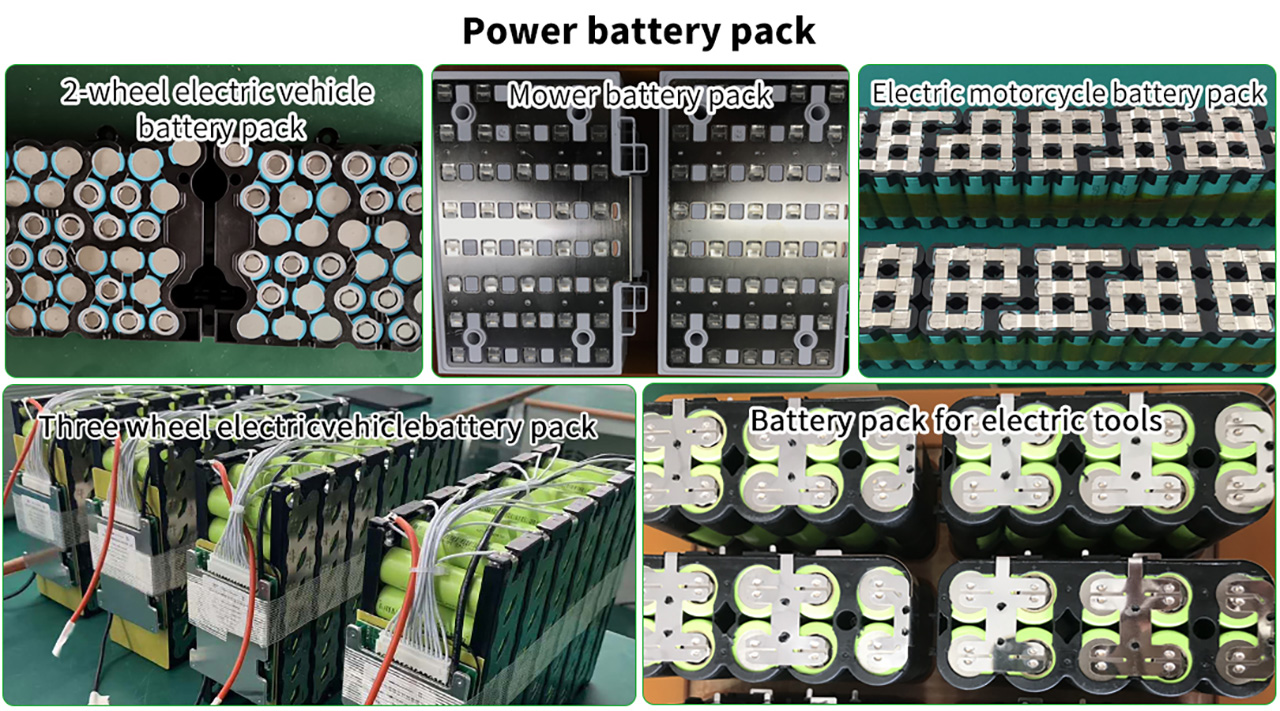

The power on inspection of lithium battery intelligent spot welder is necessary when we use the spot welder, which is an important link when using the spot welder.Sometimes electric leakage may occur in electrical equipment. It is not ruled out that leakage may also occur in our air circuit system, so we must check it before use to ensure the safety of our production.Power battery spot welder

Application Areas

The lithium battery intelligent spot welding machine is a resistance welding method in which the weldment is assembled with a joint, pressed between two electrodes, and the base metal is melted by resistance heat to form a solder joint.Spot welding is mostly used for the connection of thin plates, such as aircraft skin, aircraft engine chimney, automobile cab shell, etc.

The main components of spot welding machine include frame, welding transformer, electrode and electrode arm, pressurizing mechanism and cooling water circuit.The welding transformer is a spot welding appliance, and its secondary has only one loop.

The upper and lower electrodes and electrode arms are used not only to conduct welding current, but also to transmit power.The cooling water path passes through the transformer, electrode and other parts to avoid heating during welding, and the cooling water should be connected first, and then the power switch should be connected.The quality of electrode directly affects the welding process, welding quality and productivity. Electrode materials are usually made of red copper, cadmium bronze, chromium bronze, etc;

After-sale service

The shapes of electrodes are various, which are mainly determined by the shape of weldments.When installing electrodes, pay attention to keep the upper and lower electrode surfaces parallel. The electrode plane should be kept clean and often trimmed with emery cloth or file. The technological process of spot welding is: turn on the water cooling function.Clean the surface of the weldment, and send it between the upper and lower electrodes after accurate assembly, and apply pressure to make it contact well. Ultrasonic metal spot welder

Electrify the contact surface of the two workpieces to heat, local melting, forming a nugget.Maintain pressure after power failure, so that the nugget cools and solidifies under pressure to form solder joints.Remove the pressure and take out the workpiece.Welding current, electrode pressure, power on time, electrode working surface size and other spot welding process parameters have a significant impact on welding quality.